-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

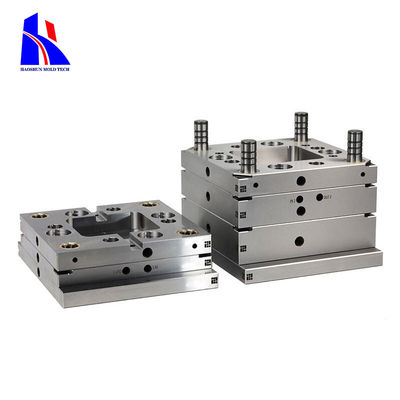

PEEK HASCO Rapid Prototype Tooling , Sandblasted Rapid Prototype Machined Parts

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | HMT |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | No MOQ Requirement |

| Price | Negotiable |

| Packaging Details | Wooden Crate, As per the mold size and customer requirement |

| Delivery Time | 15-25 Days |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability | 50 sets/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mold Material | 2738 | Surface Finishing | Sandblasted |

|---|---|---|---|

| Part Material | PEEK | Part Color | Yellow |

| Application | Medical Parts | Delivery Time | 20-45 Days |

| Packaging Details | Carton/ Wooden Case | Mould Life | 300K |

| Highlight | HASCO Rapid Prototype Tooling,PEEK Rapid Prototype Tooling,Sandblasted Rapid Prototype Machined Parts |

||

Customized Rapid Tooling PEEK HASCO 2738 Sandblasted Medical Parts Yellow

| Product range | Mold design, mold making and injection molded plastic parts production |

| Processing | Mold making fabrication, Injection molding, etc. |

| Material | ABS, PP, PPS, PC, PE, POM, PMMA, PEEK, PS, HDPE, TPE,TPU, etc. |

| Surface finish | Polishing finish,Texture Finish, High glossy, Painting, Slik print, Rubber Painting, etc. |

| Color | PANTONE/RAL color |

| Dimension | According to customer drawing |

| Mold Standard | DME, LKM, FUTA, HASCO, etc. |

| Advantages | Senior designer, Competitive price, On time delivery. |

| Mould Base | as per customer's requirement. |

| Tolerance | 0.01~0.05mm; |

| Delivery time | Mold making 4 weeks and more, injection parts 20-45 days depend on the quantity. |

| Inspection | IQC, IPQC, FQC, OQC |

| Application | All kinds of plastic injection parts, complicate plastic parts. |

FAQ

Q1:Where is your factory?

We are located in Guangzhou,China(Airport IATA: CAN, ICAO:ZGGG;Seaport: NANSHA&HUANGPU)

Q2:Avalibable for customized design drawings?

Yes, DWG,DXF,DXW,IGES,STEP,PDF ect.

Q3:Will my drawing be safe after you get it?

Yes, we can sign the NDA before you send the drawing.

Q4:What’s the MOQ?

In general 10 but can accepet low quantity in special conditions.

Q5:Do you provide samples?

Yes, just need samples cost, we will return it back in mass production.

Q6: What’s the leading time?

It depends on quantity .Generally 3-15 days afterorder confirmation.

Q7: Can we know the production process without visiting the factory?

We will offer detailed production schedule and send weekly reports with digital prictures and videos which show the machining progress.

Why Choose Us

- High Precision Mold Design and Manufacturing

- Plastic Injection Molding Production

- Mirror or Texture Molds Design and Manufacturing

- Product Total Solution Provider

- Game Station accessories design and manufacturing

- Electronic Products Design and Manufacturing

- Home Appliance Molds Design and Manufacturing

- Medical Product Molds Design and Manufacturing

- Automobile Interior Parts and Precision Accessory Design and Manufacturing

- Painting Injection Parts design and manufacturing

- Plating Parts design and manufacturing

Advantages

Short processing time, simple mold structure, movable inserts can be used to reduce time and expense.

![]()

![]()

Welcome to Get a Quote