-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

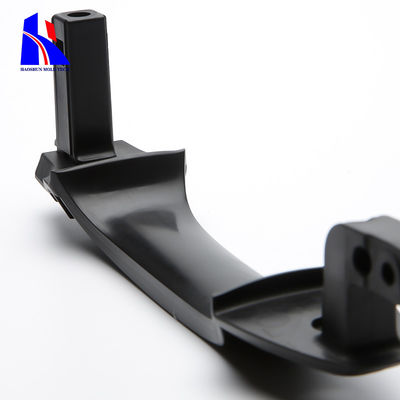

Nylon11 PP Gas Assisted Injection Moulding For Automotive Parts ISO9001

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | HMT |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | No MOQ Requirement |

| Price | Negotiable |

| Packaging Details | -Carton box with appropriate paperboard thickness -Inside care with bubble wrap or protective foam -Double inside care with cushioning materials |

| Delivery Time | 15-20 Days |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability | 2000000pcs/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Part Material | Nylon11 | Sample Cost | 12 Pcs Free Sample After Mold Trial |

|---|---|---|---|

| Color | Black | Surface Finishing | Texture, Painting |

| Runner | Cold Runner | Port | Nansha Port |

| Highlight | Nylon11 Gas Assisted Injection Moulding,ISO9001 Gas Assisted Injection Moulding,pp injection moulding automotive parts |

||

Custom Automotive Parts Gas-Assisted Injection Molding Nylon11 PP

| Part Name | Custom Automotive Parts Gas-Assisted Injection Molding Nylon11 PP |

| Part Size | As the Drawings |

| Part Material | ABS, PC, POM, ABS+PC, PMMA, Nylon, etc. |

| Color | Black, Grey, White, Yellow, Blue, As Customer's Requirements |

| Surface Finishing | Polishing, Texture, Sandblasting, Painting, Silkscreen, Laser Marking, etc. |

| Usage | For Auto Parts, For Medical Parts, For Household Parts, etc |

| Mold Standard | HASCO, DME, As Customer's Requirements |

| Mold Life | 5K-1000K Shots |

| Mold Material | 718H, NAK80, S136H, 2738, 2343, 2344, etc. |

| Runner | Cold Runner, Hot Runner |

| Payment Term | 50% Deposit, 50% Balance Payment Before Delivery |

| Quality System | ISO9001 |

Reinforces ribbed parts

Increased design options for complex parts, reducing multiple part assemblies, and metal to plastic conversions

Enables use of smaller plastic injection molding presses

In gas assist plastic injection molding, the pressurized gas follows the path of least resistance and displaces the plastic material in the thicker areas of the part, leaving hollow sections for reduced material use and part weight, yet not compromising part appearance or functional performance.

With gas assist molding, localized gas pressure within the mold results in better packing of the plastic which reduces warpage, shrinking, surface blemishes, sink marks and internal stress. Gas assist injection molded plastics generally make for stronger and more aesthetically pleasing parts.

Gas assist molding is used to reinforce ribbed parts and provides more design freedom for complex parts, reducing multiple part assemblies and metal to plastic conversions.

The need for less plastic material and the consistent pressurization within the mold also enable gas assist injection molded plastics to cool faster, reducing cycle times and increasing plastic injection molding machine output – saving time and cost!

In gas assist plastic injection molding, the internal pressure provided by the nitrogen gas enables lowering the outer force needed to hold part shape, so large plastic parts can be produced with less tonnage on smaller plastic injection molding machines.

WHY CHOOSE US?

1. One Stop Service

We can offer part design, model building, rapid prototype testing and injection molding mass production services.A range of surface finishing, post-processing and assembly are also workable. Can bring you a convenient and efficient experience.

2. Non Disclosure Agreement

We can sign NDA with you and keep secret to your idea and design.

3. Professional Engineering Team

We have a professional engineering team, half of whom have more than 15 years of experience in the mold industry, especially tooling, pleastic molding products, CNC machining and 3D printing.

4. Fast Delivery Time

We have advanced technology processing machines and time-mobilized staffs, so can finish prototype project within 3-5 days, prototype mold within 15 days, and 3-5 weeks to make mass production complex mold.

5. Quality Control Expert

We have passed ISO9001 Quality Management System Certification, having onsite materials, toolings and parts inspection before production and delivery.

6. Experienced Business Development Team

We have 15 business development specialists with good English capabilities and communication skills to know your need timely.

![]()

![]()

![]()

![]()

![]()

![]()

Welcome to Get a Quote