-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

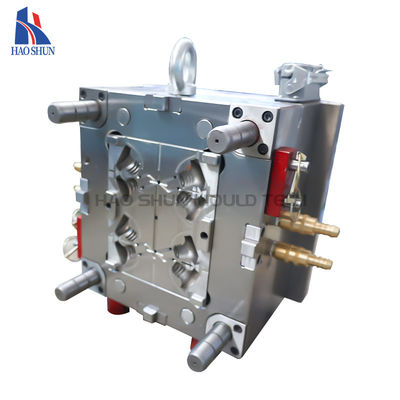

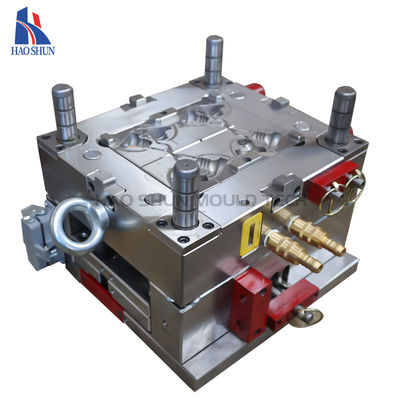

Multi Cavity Injection Tooling Mold For Medical Plastic Parts

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | HMT |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | No MOQ Requirement |

| Price | Negotiable |

| Packaging Details | Wooden Crate, As per the mold size and customer requirement |

| Delivery Time | 14-30 Working Days |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union |

| Supply Ability | 50 sets/month |

| Steel Material | NAK80, 738H, P20, Etc. | Runner | Hot Runner |

|---|---|---|---|

| Cavity | Multi Cavity | Gate Type | Hot Runner Open Nozzle |

| Tolerance | +-0.1mm | Part Material | ABS, As Customers' Requirements |

| Part Color | Blue, As Per Customer Requirements | Free Sample | Yes, 12 PCS T1 Free Sample |

| Highlight | Multi Cavity Injection Tooling Mold,Medical Plastic Injection Tooling Mold,738H Injection Tooling Mold |

||

Multi Cavity Injection Tooling Mold Manufacturers for Medical Plastic Parts

PRODUCTIONS DESCRIPTION

| Company Name | Guangzhou Haoshun Mold Tech Co., Ltd |

| Part Dimension | As the Models and Drawings |

| Color | White, Black, Yellow, Red, As Customers' Requirements |

| Surface Finishing | Polishing, Texture, Sandblasting, Painting, Silkscreen, Laser Marking, etc. |

| Company Type | Factory, Manufacturer |

| Main Service | Injection Mould/Tooling, Plastic molding parts, Structural foam molding parts, Gas- assisted molding parts, Prototype, Die casting, etc. |

| Mold Precision | +/-0.1mm |

| Gate Type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mold Cavity | Single cavity, Multi-cavity |

| Mold Base | SD, LKM Standard, HASCO Standard Self-made, etc. |

| Mold Material | P20/718/738/NAK80/S136/2738/2316/H13, etc. |

| Mold Life | 10K-1000K Shots |

| Runner | Hot Runner (YUDO) |

| Pls Provide | 2D Drawing / 3D Model File / Samples / the size of the multi-angle pictures |

| Quality System | ISO9001 |

![]()

![]()

ABOUT US

Our company was founded in 2007. We're the manufacturer specialized in injection mold/tooling, plastic molded parts and rapid prototype by 3D printing, CNC machining and vacuum casting.

And we have passed the ISO9001 quality management system, so we have committed to providing customers with standardized services. Also, we would like to growing up with the customers to expand the business and achieving win-win cooperation.

Please provide the part 3D model in STEP format or drawings for us to further check and quote an accurate cost. Looking forward to work with you!

![]()

WHY CHOOSE US?

1. One Stop Service

We can offer the service from part design to the assembly, including the model building, rapid prototype testing and injection molding mass production, a range of surface finishing, post-processing. A convenient and efficient experience for you!

2. Non Disclosure Agreement

We can sign Non Disclosure Agreement with you and keep secret to your design and project.

3. Professional Engineering Team

We have a professional engineering team, half of our engineers have more than 15 years of experience in the mold industry, especially in tooling, plastic molding products, CNC machining and 3D printing field.

4. Fast Delivery Time

We have advanced technology processing machines and time-mobilized staffs, so can finish prototype project within 3-5 days, prototype/sample mold within 15 days, and 3-5 weeks to make mass production complex mold.

5. Quality Control Expert

We have passed ISO9001 Quality Management System Certification, having onsite materials, toolings and parts inspection before production and Shipment.

6. Experienced Business Development Team

We have 15 business development specialists with good English capabilities and communication skills to know your need timely.

FAQ

Q1:Where is your factory?

We are the factory and located in Guangzhou.

Q2:Avalibable for customized design drawings?

Yes, DWG,DXF,DXW,IGES,STEP,PDF ect.

Q3:Will my drawing be safe after you get it?

Yes, we can sign the NDA before you send the drawing.

Q4:What’s the MOQ?

In general 10 but can accepet low quantity in special conditions.

Q5: Can we know the production process without visiting the factory?

We will offer detailed production schedule and send weekly reports with digital prictures and videos which show the machining progress.