-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

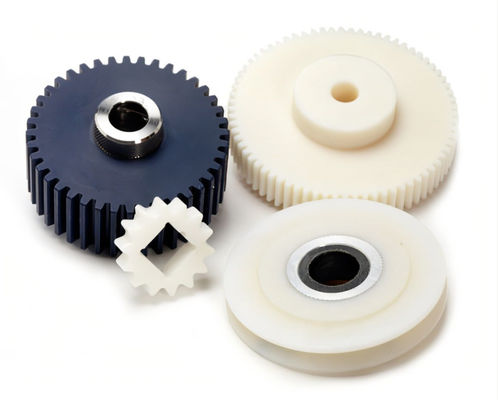

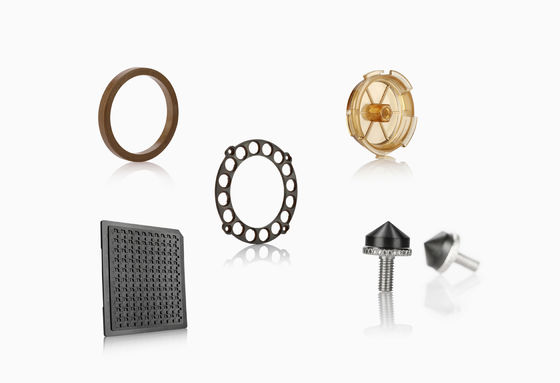

Custom Black White Plastic Injection Molding Parts Made By ABS

| Place of Origin | China |

|---|---|

| Brand Name | HMT |

| Certification | ISO9001 |

| Model Number | ODM/OEM |

| Minimum Order Quantity | No MOQ Requirement |

| Price | Negotiable |

| Packaging Details | -Carton box with appropriate paperboard thickness -Inside care with bubble wrap or protective foam -Double inside care with cushioning materials |

| Delivery Time | 15-20 Days |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability | 2000000pcs/month |

| Price | Negotiation(as Design) | Mould Material | NAK80 |

|---|---|---|---|

| Payment Terms | T/T,L/C,etc | Cavity | Single/Multi Cavity |

| Product Material | 718H, NAK80, S136H, 2738, 2343, 2344, Etc. | Color | Black, White, Customized |

| Surface | Polishing, Texture, Sandblasting, Painting, Silkscreen, Laser Marking, Etc. | File Accepted | PDF, STEP, Etc |

| Highlight | ABS Plastic Injection Molding Parts,Painting Surface Plastic Injection Molding Parts |

||

Mold Making Processes

Mold making is a complex process that requires a high level of skill and experience. Although each case is different, a typical order for a set of molds may go something like this:

1. DFM

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, etc.

2. Mold design and mold flow analysis

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design..

3. CNC machining and EDM

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer.

4. T1 sample

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

Product Display

![]()

| Items | Quantity | Remarks |

| High Speed CNC Machines | 10 | The speed can up to 24000 revolutions per minute |

| EDM Machines | 12 | One is Mirrordick from Japan |

| Milling Machine | 7 | Machining for the planes, grooves, and various surfaces |

| Drilling Machine | 1 | Machining holes in materials |

| Wire Cutting | 10 | Used in all kinds of mould manufacturing and special parts processing |

| Surface Grinder | 5 | For grinding workpiece planes and forming surfaces |

| Traveling Crane | 2 | For moving the mold components and molds |

| Injection Machines | 21 | From 50 tons to 1250 tons |

| Gas Assisted Machines | 1 | Fit for thick and small parts |

Welcome to Get a Quote