-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

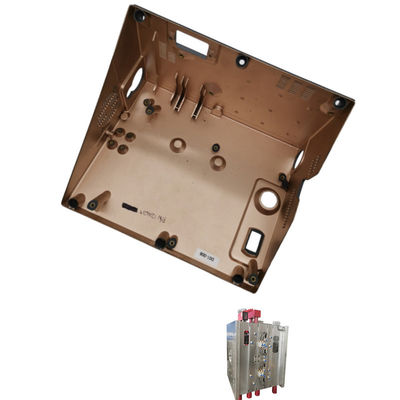

Cold Runner Plastic Injection Molded Parts With EMI Coating

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | Custom |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | No MOQ Requirement |

| Price | Negotiable |

| Packaging Details | -Carton box with appropriate paperboard thickness -Inside care with bubble wrap or protective foam -Double inside care with cushioning materials |

| Delivery Time | 10-20 Working Days |

| Payment Terms | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability | 2000000pcs/month |

| Plastic Material | PC/ABS | Color | Gray, As Customers' Requirement |

|---|---|---|---|

| Part Size | As The Model Drawing | Application | Electronic Industry |

| Surface Finished | EMI Painting | Runner | Cold Runner |

| Cavity | Single Cavity | Quality Control | Full Inspection Before Delivery |

| Highlight | Cold Runner Plastic Injection Molded Parts,EMI Coating Plastic Injection Molded Parts |

||

PC/ABS Material Plastic Injection Molded Parts With EMI Coating

| Product Description: | Plastic injection mold |

| Plastic Materials: | PC/ABS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D Drawing, 3D Model |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed, as per the model |

| Package: | Standard exported Wooden box packed, Fumigation process (upon required) |

| Mold Building Lead Time: | T1, 3-5 weeks, FAI Part measurement report (upon required). |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Compression Mold, etc. |

| Mould Standard: | Hasco Standard, European Standard, GB Chinese Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,..etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture (MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your requirements) |

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-1250T available. |

WHY CHOOSE US?

| One-stop Service | We can offer one-stop service, from part design to 3D model building, rapid prototype sample testing, injection molding mass production, surface finshing, post processing and assembly services. |

|

Non Disclosure Agreement

|

We can sign NDA/NNN Agreement with you and protect your idea and design. |

| Professional Engineering Team | We have a professional engineering team, many of them are having more than 15 years experience in the tooling industry, especially in tooling, plastic molding parts, CNC machining and 3D printing field. |

| Fast Delivery Time |

We have time-mobilized staffs, so can finish prototype project within 3-5 days, prototype mold within 15 days, and 3-5 weeks to make mass production complex mold. For the production order, we can finish within a week, just as per the order quantity and order schedule. |

| Quality Control Expert | We have passed ISO9001 Quality Management System Certification, having onsite materials, toolings and parts inspection before production and the shipment. |

|

Experienced Business Development Team

|

We have 15 business development specialists with good English capabilities and communication skills to know your need timely. |

OUR FACTORY

Guangzhou Haoshun Mold Tech Co., Ltd (HMT) was founded in 2007 with 110+ employees, covers 5000㎡, it's a professional manufacturer specialized in prototyping (3D printing / CNC machining / Vacuum casting), toolmaking and plastic molded production. We have 21 injection machines ranging from 50 to 1250 tons, the biggest plastic part we can produce is 1260mm, weight 4.5KG. And now we're expanding our machines quantity and production lines to meet the increased orders and the faster delivery time.

We’ve been committed to provide varied prototype like 3D printing, CNC machining and Vacuum casting, Toolings and Injection molded products for our customers in high quality with short delivery time. And we have passed ISO9001 quality management system certification in 2015. Under the ISO9001 quality control system, it standardizes our factory scientific management comprehensively.

Plastic injection molding is the most common industry way to manufacture plastic parts, especially when making larger quantities. Please feel free to send the part 3D models in .STEP format or 2D drawings for us to further check and quote an accurate tooling cost and part unit cost.

Let's do business!

![]()

![]()

FAQ

Q1: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D STEP of files and 2D drawings

2) Material

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as package, labels, delivery, etc.

Q2: What’s the MOQ?

We do not have the MOQ requirements, 1 piece sample for testing is also acceptable for us, we can do 3D printing / CNC machining for you. And we can accepct low volume production for you.

Q3: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.