-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

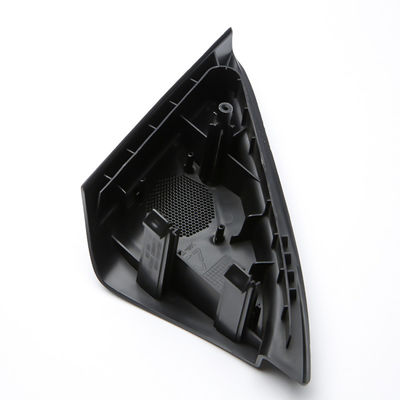

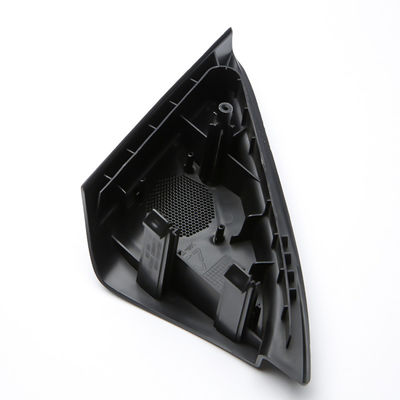

ISO9001 Certified Automotive Plastic Injection Molding Parts with 15-30 Delivery Time

| Place of Origin | Guangzhou, Guangdong |

|---|---|

| Brand Name | N/A |

| Certification | ISO9001 |

| Model Number | Custom |

| Minimum Order Quantity | 1 |

| Price | TBD |

| Delivery Time | 7~15 working days |

| Payment Terms | 50% deposit payment upon ordering, 50% balance before shipment |

| Supply Ability | Plastic injection molding parts, plastic injection mold |

| Size | Customized | Design | .STEP 3D / 2D Drawing |

|---|---|---|---|

| Lead Time | 15-30 Days | Shape | Customized |

| Package | Carton, Wooden Pallet, Etc. | Surface Finish | Polishing, Sandblasting, Texture, Painting, Etc. |

| Certificate | ISO9001 | Process | Injection Molding |

ISO9001 Certified Automotive Plastic Injection Molding Parts with 15-30 Delivery Time

Product Description:

The Plastic Injection Molding Parts are a type of product that is widely used in many industries due to their versatility and cost-effectiveness. These parts are made through the process of injection molding, which involves injecting molten plastic material into a mold to form a specific shape. This allows for the creation of complex and precise parts that are essential in the production of various products.

One of the main advantages of Plastic Injection Molding Parts is their ability to be customized according to specific requirements. This means that the size, shape, and design of the parts can be tailored to meet the exact needs of the customer. We have a team of experienced engineers who use the latest technology to create parts that are not only functional but also aesthetically pleasing.

Our MOQ (Minimum Order Quantity) requirement for Plastic Injection Molding Parts is flexible. We understand that different customers have different needs, and we are committed to meeting those needs. This means that we do not have a strict MOQ requirement, and we are willing to work with our customers to find a solution that works for them.

For the design of our Plastic Injection Molding Parts, we use .STEP 3D and 2D drawings. This allows for accurate and detailed designs that can be easily translated into the final product. Our team is proficient in using these design tools and can work closely with our clients to ensure that their vision is brought to life.

The process of Injection Molding is the backbone of our Plastic Injection Molding Parts. This process involves injecting molten plastic material into a mold under high pressure and then allowing it to cool and solidify. This results in a strong and durable part that can withstand various environments and conditions. Our state-of-the-art molding machines and skilled technicians ensure that the parts are produced to the highest quality standards.

At our company, we take quality seriously. That is why we have obtained the ISO9001 certificate, which is a globally recognized quality management system. This means that our Plastic Injection Molding Parts are manufactured in accordance with the highest quality standards. We also have a rigorous quality control process in place to ensure that each part meets our customers' expectations.

In conclusion, our Plastic Injection Molding Parts are highly versatile, customizable, and of the highest quality. We have no strict MOQ requirement and use the latest technology and processes to create parts that meet our customers' needs. Our ISO9001 certification is a testament to our commitment to providing top-notch products to our clients. Contact us today to discuss your Plastic Injection Molding Part needs!

Technical Parameters:

| Product Name | Plastic Injection Molding Parts |

|---|---|

| MOQ | No MOQ Requirement |

| Lead Time | 15-30 Days |

| Size | Customized |

| Surface Finish | Polishing, Sandblasting, Texture, Painting, Etc. |

| Logo | Customized |

| Package | Carton, Wooden Pallet, Etc. |

| Shape | Customized |

| Design | .STEP 3D / 2D Drawing |

| Tolerance | ±0.05mm |

| Color | Customized |

Applications:

Plastic Injection Molding Parts are widely used in various industries such as automotive, electronics, medical, and consumer goods. These parts are produced through the process of injection molding, which involves injecting molten plastic into a mold and allowing it to cool and solidify into the desired shape. This process offers high production efficiency, cost-effectiveness, and the ability to create complex and precise parts.

- Brand Name: N/A

- Model Number: Custom

- Place of Origin: Guangzhou, Guangdong

- Certification: ISO9001

- Minimum Order Quantity: 1

- Price: TBD

- Delivery Time: 7~15 working days

- Payment Terms: 50% deposit payment upon ordering, 50% balance before shipment

- Supply Ability: Plastic injection molding parts, plastic injection mold

- Material: ABS, PC, PC/ABS, Nylon, POM, PMMA, PEEK, Etc.

- MOQ: No MOQ Requirement

- Design: .STEP 3D / 2D Drawing

- Tolerance: ±0.05mm

- Process: Injection Molding

Plastic Injection Molding Parts have a wide range of applications and are used in various scenarios. Some examples are:

In the automotive industry, plastic injection molding parts are used in the production of interior and exterior components such as dashboards, door panels, bumpers, and engine parts. These parts are lightweight, durable, and have excellent design flexibility, making them ideal for use in cars.

The electronics industry relies heavily on plastic injection molding parts for the production of components such as computer and phone casings, keyboards, and connectors. These parts offer high precision and can be customized to meet specific design requirements.

In the medical industry, plastic injection molding parts are used in the production of medical devices and equipment such as syringes, IV bags, and surgical instruments. These parts are made from medical-grade materials and are produced with strict adherence to quality and safety standards.

Plastic injection molding parts are also commonly used in the production of consumer goods such as household appliances, toys, and packaging materials. These parts offer cost-effectiveness and can be produced in large quantities, making them ideal for mass production.

Plastic Injection Molding Parts are a versatile and essential component in many industries. With their customizability, efficiency, and cost-effectiveness, they continue to play a vital role in the production of various products. As technology and materials continue to advance, the use of plastic injection molding parts is expected to grow even further in the future.

Customization:

Brand Name: N/A

Model Number: Custom

Place of Origin: Guangzhou, Guangdong

Certification: ISO9001

Minimum Order Quantity: 1

Price: TBD

Delivery Time: 7~15 working days

Payment Terms: 50% deposit payment upon ordering, 50% balance before shipment

Supply Ability: Plastic injection molding parts, plastic injection mold

Process: Injection Molding

Size: Customized

Application: Automotive, Medical, Electronic, Etc.

Logo: Customized

Package: Carton, Wooden Pallet, Etc.

- High-quality plastic injection molding parts

- Customized according to specific requirements

- ISO9001 certified for quality assurance

- Short lead time of 7~15 working days

- Flexible payment terms with 50% deposit payment and 50% balance before shipment

- Wide range of applications in automotive, medical, electronic industries, etc.

- Customized logo for brand recognition

- Safe packaging in cartons or wooden pallets for secure transportation

Packing and Shipping:

Our Plastic Injection Molding Parts are carefully packaged to ensure safe and secure delivery to our customers. We understand the importance of protecting these delicate parts during transportation. Therefore, we use high-quality packaging materials to ensure that your order arrives in perfect condition.

All parts are individually wrapped and then placed in a sturdy cardboard box. Depending on the size and quantity of your order, we may use bubble wrap or foam inserts to provide additional protection. Each box is labeled with the part number and quantity for easy identification and inventory management.

For larger orders, we use pallets to ensure safe transportation. The parts are securely stacked and strapped to the pallet to prevent any movement during shipping. We also use shrink wrap to further secure the parts and protect them from any external elements.

We work with trusted shipping companies to ensure timely delivery of your order. Our team carefully monitors the shipping process to ensure that your order is delivered to you on time and in perfect condition.

Upon arrival, please inspect your order carefully. If there are any damages or issues, please contact us immediately so we can resolve the issue and ensure your satisfaction.

Warly welcome to get an inquiry from us!