-

Plastic Injection Molding Parts

-

Structural Foam Injection Moulding

-

Gas Assisted Injection Moulding

-

Plastic Injection Overmolding

-

Toolmaking Services

-

Rapid Prototype Tooling

-

3D Printing Rapid Prototyping Services

-

Vacuum Casting Prototype

-

CNC Machining Parts

-

Sheet Metal Rapid Prototyping

-

Surface Finishing Services

-

Pressure Die Casting Parts

-

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far!

Nate G.I really appreciated your working with us on the change and all throughout the process. If there's a possibility to give positive feedback, I'd love to do so. It's been great working with Haoshun so far! -

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality!

Kevin W.We received your package of the molded parts. They look and function GREAT, so thank you very much. We are very impressed with your quality! -

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

Mr. G. TaylorWe greatly appreciate your team's support and the quality of the work. I'm super happy by your service and quality, thank you very much!

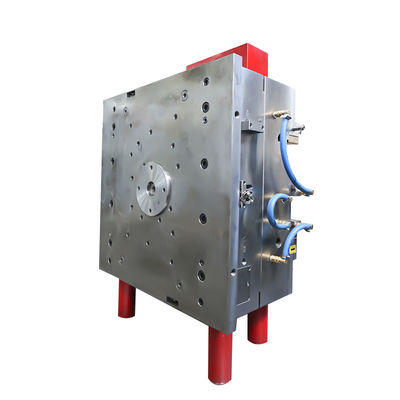

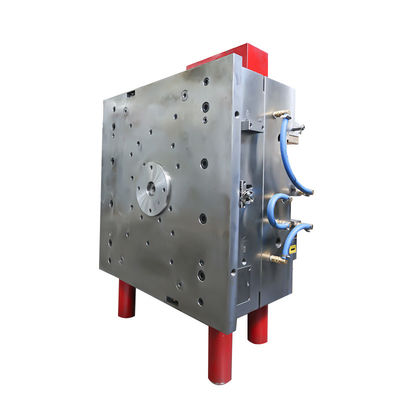

738 Steel Injection Mold Making Services for Customized Plastic Parts with Texture

| Steel Material | 738, 2344, 2343, 2316, Etc. | Gate Method | Pin Point Gate, Edge Gate, Sub Gate |

|---|---|---|---|

| Color | White, Customized | Production Process | Design, Prototyping, Machining, Finishing |

| Model Numbe | Custom | Lead Time | Varies Depending On Complexity And Quantity |

| Materials Used | Steel For Molds, Plastic For Parts | Sample | 12 PCS T1 Free Samples |

738 Steel Injection Mold Making Services for Customized Plastic Parts with Texture

Product Description:

Our Toolmaking Services provide you with a Sample of 12 PCS T1 Free Samples to ensure that you are satisfied with the quality of our work before proceeding with production. We understand that the quality of your product is of the utmost importance, and we strive to provide you with the best possible service to ensure your success.

Our molds have a long Mold Life of 10K~1000K, ensuring that you get the most out of your investment. Our team of experts uses only the highest quality Steel For Molds and Plastic For Parts to ensure that your molds are durable and reliable, even with regular use.

Our Toolmaking Services pride themselves on providing a Tolerance of +-0.1mm. This means that your molds will be created with the utmost precision and accuracy, ensuring that your product is of the highest quality possible.

The Steel Material used in our Toolmaking Services is 738, which is known for its durability and reliability. With this material, you can be sure that your molds will last for a long time and provide you with consistent results.

In summary, our Toolmaking Services provide you with high-quality Injection Mold Making services that are reliable, accurate, and durable. With our Sample of 12 PCS T1 Free Samples, long Mold Life of 10K~1000K, high-quality Steel For Molds and Plastic For Parts, Tolerance of +-0.1mm, and Steel Material of 738, you can be sure that your product will be of the highest quality possible. Trust our Toolmaking Services to provide you with the best possible service and the best possible outcome for your product.

Features:

- Product Name: Toolmaking Services

- Tolerance: +-0.1mm

- Steel Material: 738

- Gate Type: Edge Gate

- Gate Method: Pin Point Gate, Edge Gate, Sub Gate

- Production Process:

- Design

- Prototyping

- Machining

- Finishing

Our Toolmaking Services offer Injection Mould Manufacturing, Injection Die Making, and Injection Tooling Making with high precision and accuracy.

Technical Parameters:

| Product Attribute | Description |

|---|---|

| Product Name | Toolmaking Services |

| Product Type | Injection Mould Manufacturing, Plastic Mould Making, Injection Die Making |

| Sample | 12 PCS T1 Free Samples |

| Material | Nylon, Customized |

| Gate Type | Edge Gate |

| Production Process | Design, Prototyping, Machining, Finishing |

| Lead Time | Varies Depending On Complexity And Quantity |

| Materials Used | Steel For Molds, Plastic For Parts |

| Tolerance | +/-0.1mm |

| Color | White, Customized |

| Gate Method | Pin Point Gate, Edge Gate, Sub Gate |

| Steel Material | 738 |

Applications:

Our molds are certified under ISO 9001, ensuring that they meet the highest quality standards. We offer a minimum order quantity of 1 with a delivery time of 20~30 working days. Our molds have a mold life of 10K~1000K and come with a variety of gate methods such as Pin Point Gate, Edge Gate, and Sub Gate. We also offer customization for our clients with custom model numbers and the option of a hot runner or cold runner.

Our Toolmaking Services product offers injection tooling making for a variety of applications. Our molds are suitable for making products for the automotive industry, electronic industry, medical industry, and more. Our molds can be used to create products such as car parts, electronic components, and medical devices.

Our Toolmaking Services product provides injection die making for a variety of scenarios. Our molds can be used for high volume production runs or for smaller scale projects. We offer 12 PCS T1 free samples to help our clients test and refine their products before going into full production.

Our Toolmaking Services product comes with wooden crate packaging details, ensuring that our molds are protected during transportation. We also require a 50% deposit upon ordering and a 50% balance payment before shipment.

Overall, our Toolmaking Services product is an essential service for companies in need of high-quality injection molds. Our certifications, customization options, and variety of gate methods make our molds suitable for a variety of applications.

Support and Services:

Our Toolmaking Services product comes with comprehensive technical support and services to ensure the smooth functioning of your tools. Our team of experienced technicians is available to provide assistance with tool maintenance, repair, and calibration. In addition, we offer training and consulting services to help you optimize the use of your tools and address any technical issues that may arise. Our commitment to customer satisfaction means that we are always available to answer any questions and provide personalized support to meet your unique needs.

Packing and Shipping:

Product Packaging:

Our Toolmaking Services product is carefully packaged to ensure its safety during transit. The product is securely wrapped in bubble wrap and placed in a sturdy cardboard box. The box is then sealed with packaging tape to prevent any damage during shipping.

Shipping:

We offer fast and reliable shipping services to ensure that our customers receive their Toolmaking Services product as quickly as possible. We use trusted shipping carriers to deliver the product directly to the customer's address. The shipping cost is calculated based on the weight and destination of the package. Once the product is shipped, customers will receive a tracking number to monitor the status of their delivery.